▉Special thanks:

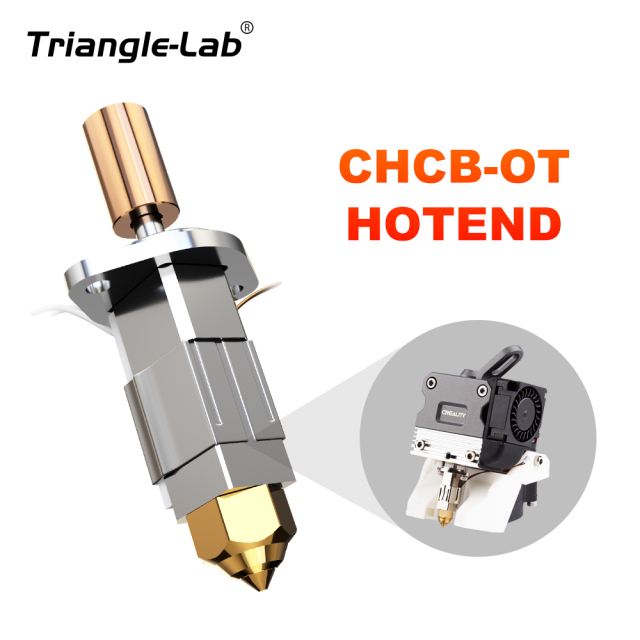

Through a remarkable collaboration, Omranello's visionary insights and TriangleLab's engineering prowess converged to craft the exceptional CHCB-OT hotend, redefining possibilities in 3D printing technology. Omranello + TriangleLab is proud to introduce our newest CHCB-OT to the community, enhancing the capabilities of Creality Printers.

you can follow his 3D journey, upgrades, and creations on

youtube.com/@omranello

Instagram.com/omranello

▉Name:

CHCB-OT HOTEND KIT

▉Description:

CHCB-OT hotend is a hot end component, it can directly replace the original hot end on Creality K1 or K1MAX or CR-M4 printer.

It made of better material, a higher flow rate and an easier maintenance design.

▉Highlight:

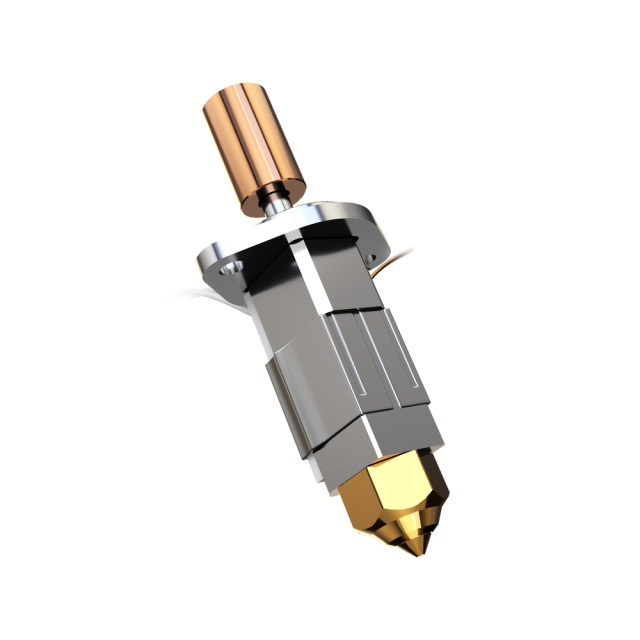

1.Planar contacts heating element have a more certain contact than ceramic heating ring contacts

2.compared to the original OT hotend heating elements and thermistors are easy to maintain and replace

3.Separate design of fixed flange and heating core.

The flange is made of a material with a low thermal conductivity to reduce the working temperature of the heat sink fixed with it by screws.

4.Compatible with various MK8 series nozzles that are readily available.

5.Drop-in replacement for the hotend of the Creality K1 /Creality K1 MAX and CR-M4 printer.

6.Can be direct installed on Creality Sprite Extruder to increase flowrate by 50%.

▉About compatibility

Creality K1 / K1 MAX

Ender3 V3 KE

Ender3 V3 SE*

Creality CR-M4

CR-10 Smart Pro

Ender3 S1 ▉What's in the set?

▉What's in the set?

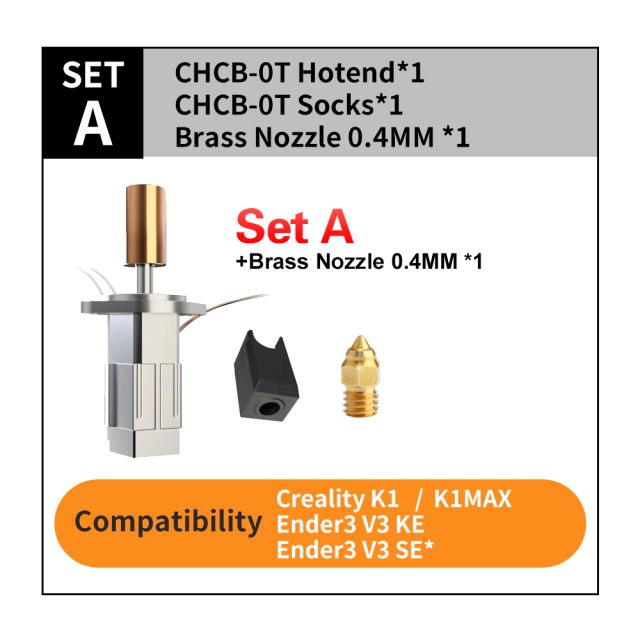

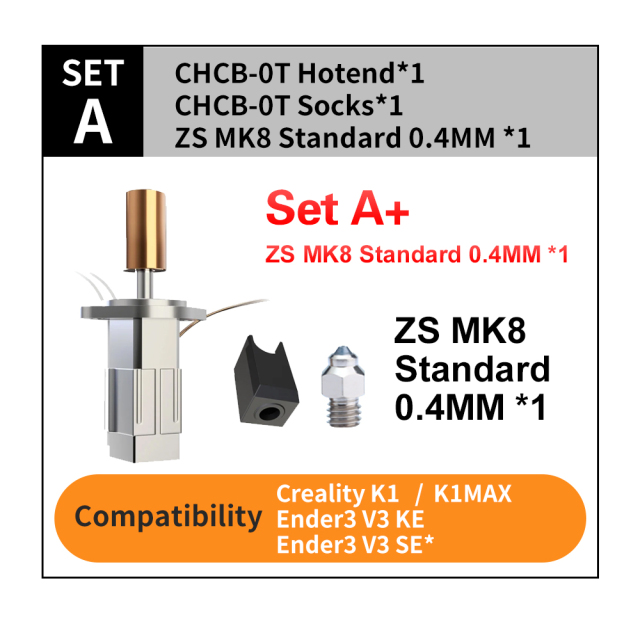

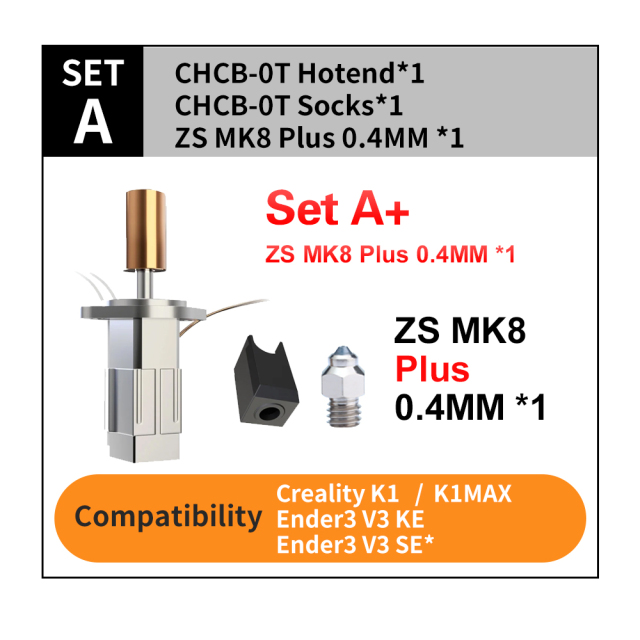

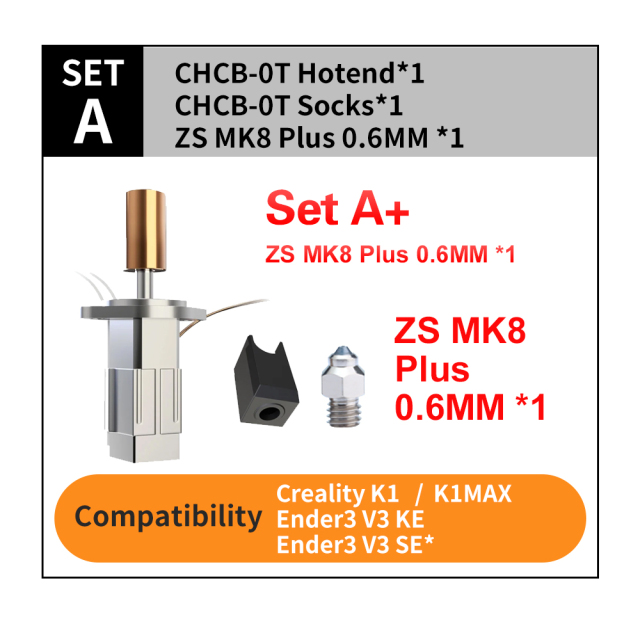

SET A

CHCB-0T Hotend*1

CHCB-0T Socks*1

Compatibility

CrealityK1 /KIMAX

Ender3 V3 KE

Ender3 V3 SE

* Fan duct modifications are required, such as:

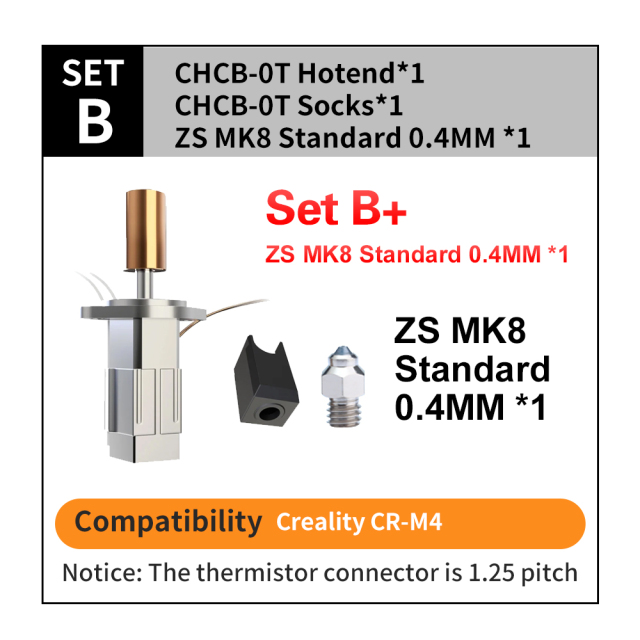

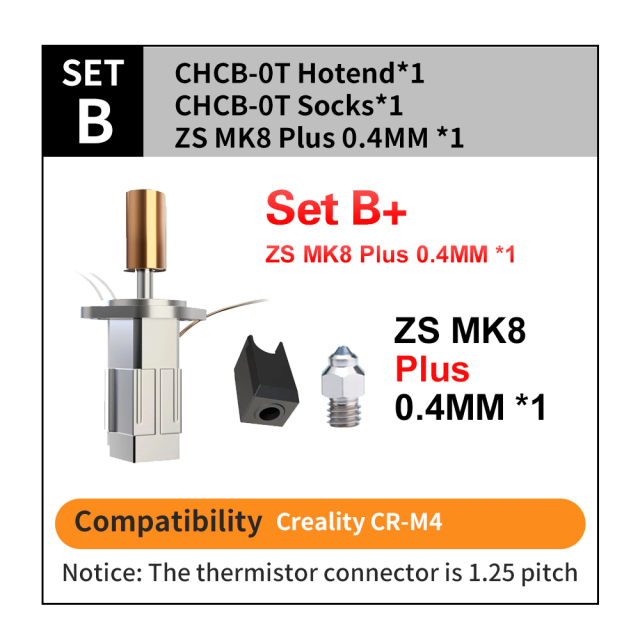

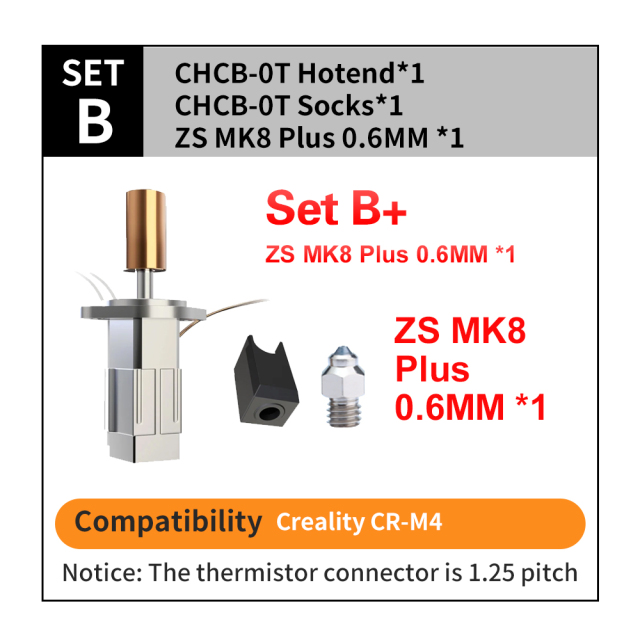

CHCB-0T Hotend*1

CHCB-0T Socks*1

Compatibility

Creality CR-M4

Notice: The thermistor connector is 1.25 pitch SET C

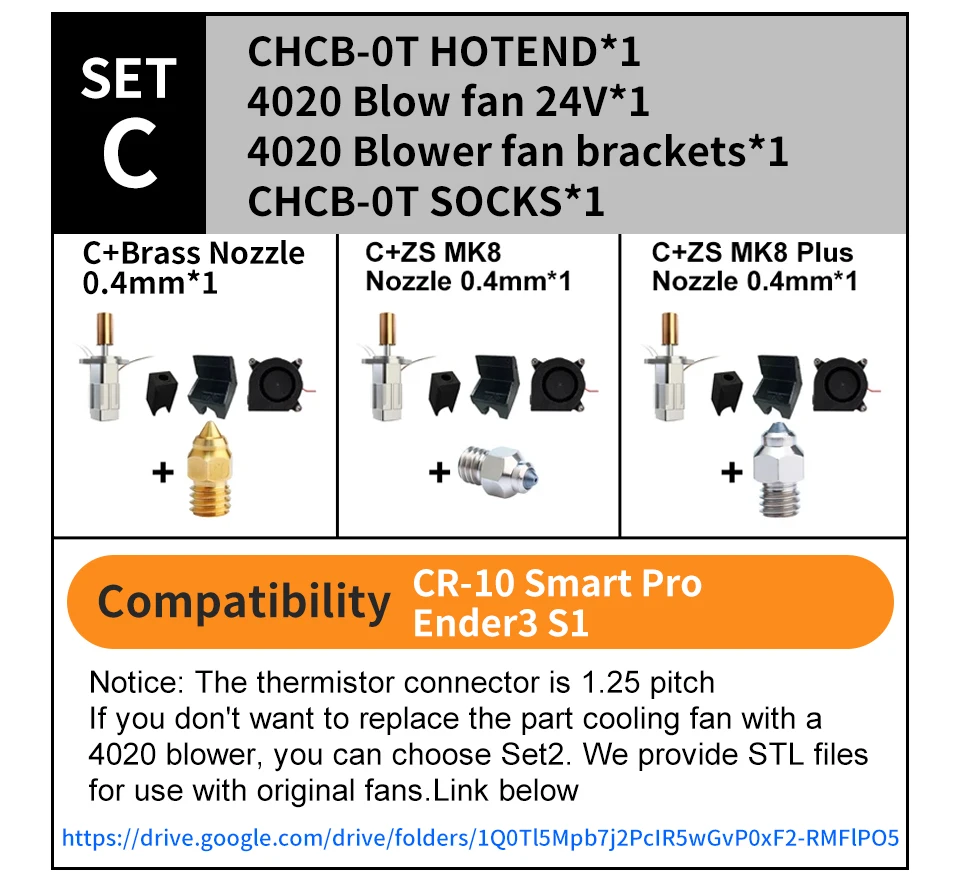

SET C

CHCB-0T HOTEND*1

4020 Blow fan 24V*1

4020 Blower fan brackets*1

CHCB-0T SOCKS*1

Compatibility

CR-10 Smart Pro

Ender3 S1

Notice: The thermistor connector is 1.25 pitch

If you don't want to replace the part cooling fan with a 4020 blower, you can choose Set2. We provide STL files for use with original fans.Link below

Applicable nozzle

Brass Nozzle 0.4mm

ZS MK8 Nozzle 0.4mm

ZS MK8 Plus Nozzle 0.4mm

▉Material detail:

▉Specification:

Heating element resistance value: 7.5-9.5 ohms

Nominal power: 24V 67W @24℃ (61-77W)

Thermistor: NTC 100Kohms B3950 1% (Choose 1 in marlin firmware)

▉Dimensions:

▉Documentation link:

https://drive.google.com/drive/folders/1Q0Tl5Mpb7j2PcIR5wGvP0xF2-RMFlPO5?usp=sharing

▉Test Report:

test1

Experiment introduction:

Comparing the temperature change of the cold side heat sink between the original hotend of Creality Sprite(Figure 1) and after the installation of OT hotend(Figure 2) .

Experimental conditions:

Printer: CR-10 smart PRO

Ambient temperature 26-27℃

Nozzle set temperature 250℃

Temperature measurement position:

The thermocouple probe is placed in the path of the filament, inside the heatbreaker cold side, approximately where the setscrews are located.

As shown in Figure 3 Figure 4

Experimental results:

The lower the temperature the better

1.Original hotend The measured temperature is 42.5℃ (Figure5)

2.OT hotend The measured temperature is 38.4℃ (Figure6)

Conclusion:

Under the same conditions, the temperature of the cold end of CHCB-OT hotend is lower.

The thermal creep and clogge will not easily occur compared to the original hotend.

test2

test2Test introduction:

Compare the difference between the original hotend and OThotend printouts of the K1 printer

Test conditions:

printer:Creality K1

Filament:Creality hyper PLA

G-code: 600MM/S DEMO provide by Creality K1

Test Result:

As shown in the figure, after replacing the K1 printer with an OT hotend, the finished product printed at 600MM/S with the same Gcode file, the same filament, and the same nozzle is just as good, and the surface looks basically the same. But when we apply the same destructive force on the same place, the original hotend prints have layer separation, while the OT-hotend prints only show stress whitening. This indicat that the OT hotend has a higher flow rate in which the filament is more fully melted.