RNC Nano Coated 8mm dual drive gear

*Only For 1.75mm Filament

Warning: This gear is compatible with ORBITER V1.5, but not V2.0.

HRC60+,Ultra-high hardness HV3300

The overall hardness of the hardened steel substrate reaches HRC60+

The more wear-resistant surface adopts RNC-based nano-coating, ultra-high hardness HV3300

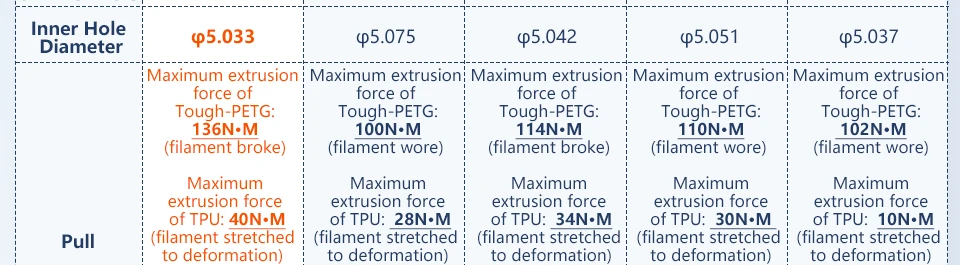

Trianglelab RNC nano coating ID:8mm gears, compared to other brands of gears tested

Size

All-metal high-temperature printing at 500+℃, compatible with multiple models.

Package list

1.TriangLab -RNC nano coating 8mm Drivegear X 1

Conclusion

1.In terms of appearance, compared with other products, Triangle Lab are smoother and finer, followed by the extrusion wheel of manufacturer B. Although there are knife lines, they are relatively fine and even

2.From the analysis of tooth profile, compared with triangular teeth, curved teeth can engage with filaments more deeply for grip force. In contrast, the tooth shape of Triangle Lab is more smoother and more symmetrical, while the other tooth shapes have obvious knife lines, and the tooth bases are uneven. After a long time, there will be serious wear, resulting in the reduction of tooth life. The tooth shape of manufacturer D can not be distinguished, and the tooth tip can not be clearly distinguished, so the durability of manufacturer D is insufficient compared with other manufacturers’ products. The tooth surface and shaft of manufacturer C's product are slightly inclined, which may be due to the machining accuracy.

3.From the dimension analysis, the tooth diameter of manufacturer A, manufacturer B and Triangle Lab is similar. Triangle Lab tooth tip is thinner, makes it easier to cut into the filaments, and the next best is Manufacturer B, but manufacturer B's tooth beat is higher than Triangle Lab. Manufacturer C's tooth tip is wider, so it is not conducive to access filaments. The tooth length analysis shows that the tooth length of Triangle Lab is shorter and closer to the diameter of filaments, so the meshing of filaments is better than other’s.

4.Tension test method: Use DDB extruder, tighten the spring after the motor is energized, draw filaments. The filaments squeezed by the extrusion wheels of manufacturer A, C and D all slipped, and the filaments were pulled off by Triangle Lab and manufacturer B.

5.In the hardness test, except the products of Triangle Lab reached HRC50 or above, the highest hardness of the other products was HRC30, which is easy to wear, especially for printing composite fiber filaments.

6.Based on the above analysis, Triangle Lab and manufacturer B’s appearance and size is better, Triangle Lab hardness is higher, and the curved teeth of Triangle Lab are recommended.

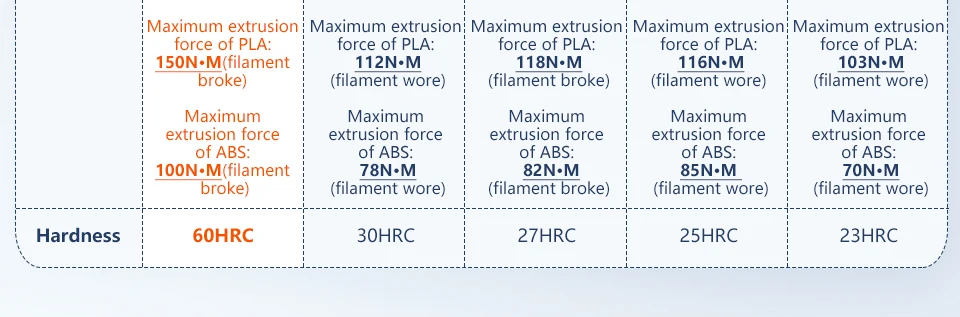

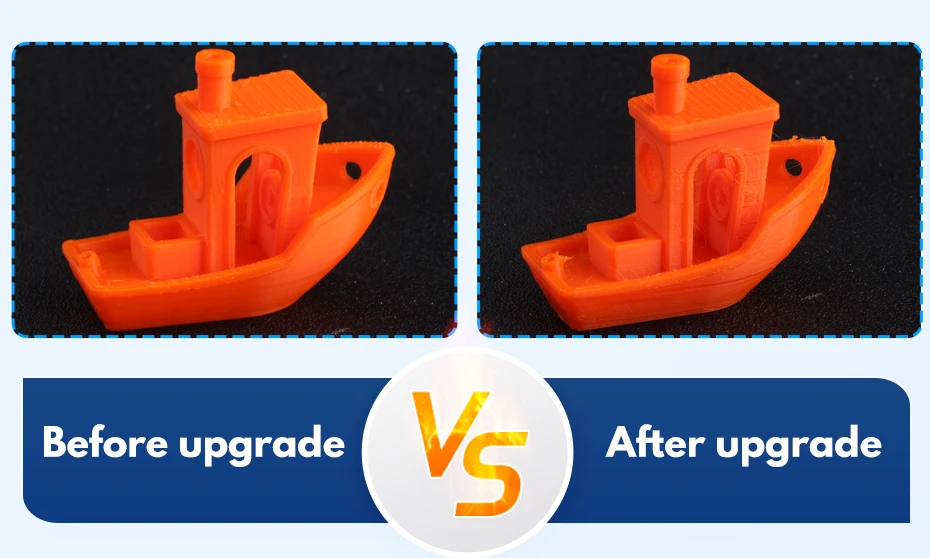

Comparison of prints before and after the upgrade

Adding to cart succeed!

items in cart.

Total:

Requires a minimum purchase of {MinPrice}. And you still need to meet the requirements.

Proceed to Checkout Return to Shopping